Why Interior car Labels are important

Your labels must withstand various conditions and surface contact over a long time. The lifespan of a standard car is 12 years or 200,000 miles on average. Sometimes, you can expect even longer lifespans depending on the engine type or how well the consumer takes care of or utilizes the vehicle.

You want your automotive labels to stand the test of time, and some examples of what you will need for your interior automotive labels include:

- Fade resistance of images and text – As direct UV rays can cause fading of the ink if exposed

- Resistance to chemicals – As many consumers will use harsh chemicals to clean and protect the interior of their vehicles

- Sharp, dark-colored images – The information printed must remain legible for 12+ years

- Resistance to extreme high and low temperatures – Vehicles will be exposed to scorching summer days or extremely Icey and cold winters

Types of Interior Car Labels

In the United States, one specific label required is called a VIN or a vehicle identification number. This label is regulated and directed by the NHTSA, a combination of roman letters and Arabic numbers assigned to each individual mortar vehicle used for identification purposes. This unique 17-character number is appointed by the manufacturer directly. It must appear sharp and clear to ensure that it will be legible for the life of the vehicle as it is not to be removed at any time unless necessary for repairs.

Other labels within the interior of a motor vehicle may be required, such as:

- Asset labels

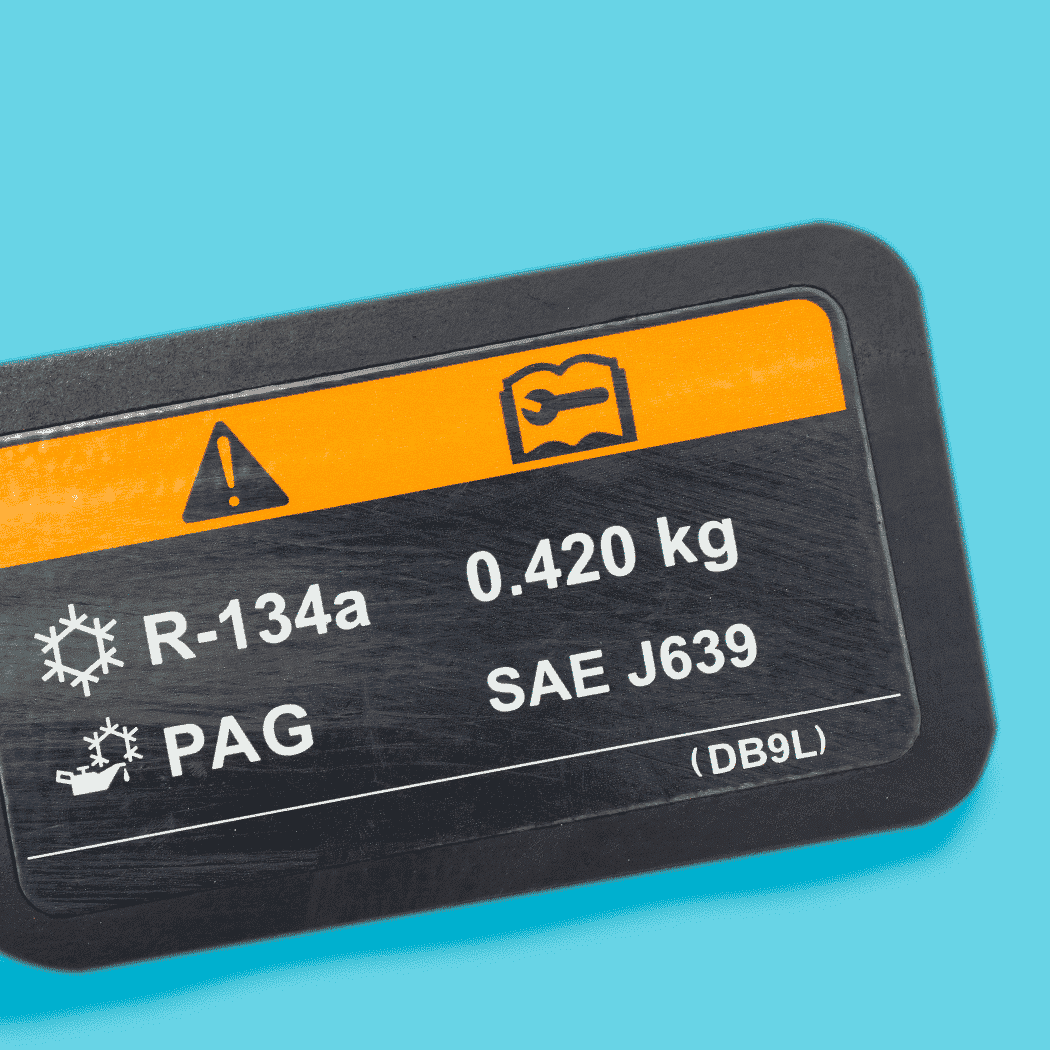

- Warning Labels

- Barcode identification

- Instructions

Applications where interior automotive labels may be applied include:

- Airbags

- Seatbelts

- Dashboard

- Seats

- Flooring & carpets

Why using thermal transfer technology for this application ?

Thermal Transfer is your solution

With the various demanding needs for these labels, you must find a reliable solution. That’s where thermal transfer ribbons come into play! With durable options such as wax/resin, resin ribbon solutions that properly apply to your needed label stock such as polypropylene, Vinyl, Polyetheylene, and more.

For this application, we recommend the following products: