Flexible Packaging Labelling

As the flexible packaging industry grows, you will see many brands shift from boxes and containers to flexible packaging options, some of these product applications may include:

- Pasta and rice

- Chips and crackers

- Frozen foods

- Uncarbonated beverages

- Condiments

- Trail mix

- Candy

- And more

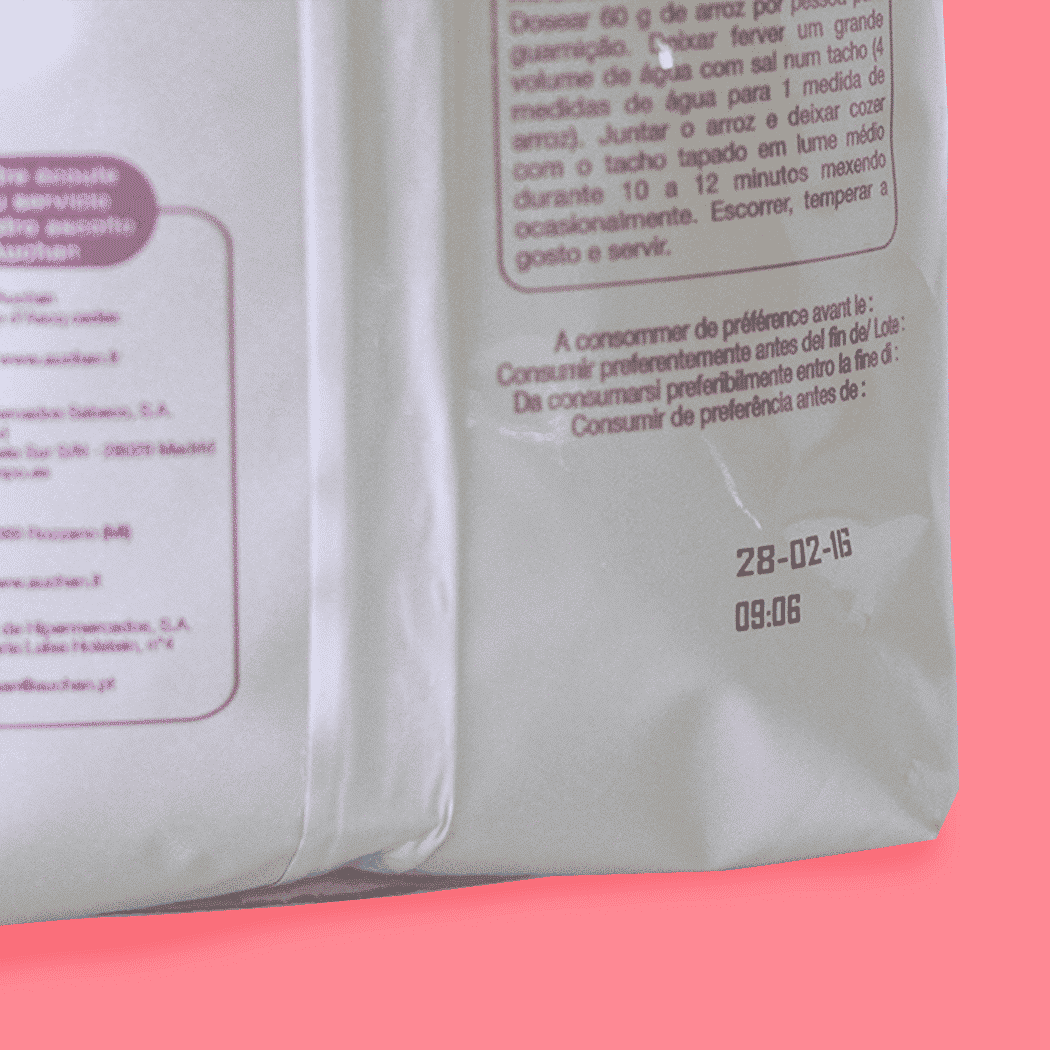

Often times you will need a reliable print technology solution to visible display variable information on your package such as date, price, and lot codes that all play a critical role in track and trace and food safety.

Optimally, this variable information is applied to packages via thermal transfer technology. What makes this print technology so ideal for flexible packaging is because thermal transfer overprinters (TTO) are integrated into vertical and horizontal form, fill and seal equipment, to maximize your production process.

Why using thermal transfer technology for this application ?

Accomplish durable thermal transfer label printing for flexible packaging

Depending on your application, you’ll want to assure that you take any durability requirements into account. An example of this may be an item that is designed to have heat applied to the product.

During the packing of hot food products such as sauces and prepared foods, the heat spreads through the packaging film and is therefore able to break down, melt, or erase the ink. This constraint can be amplified by the high speed of certain packing lines which require the use of a quick-drying ink.

Flexible Packaging Print Solutions

Thermal Transfer can offer you maximum flexibility for customizing any packaging and is able to mark all logos, numbers, barcodes, and characters.

You can avoid this print from being altered or removed by implementing an optimal thermal transfer ribbon, such as a wax/resin or resin formulation, that offers resistance to abrasion, smudging, handling, freezing, steam, heat, and chemicals.

This print technology will also provide you with the ability to comply with European regulations (1935/2004/EC) and US FDA requirements and offer excellent adhesive qualities for all types of plastic packaging, even pre-printed!

For this application, we recommend the following products: